The SG-Lib was designed for the demand-oriented design and 3D printing of mechanisms, movement machines and robots

•The objects generated by SG-Lib were validated using the following additive manufacturing processes:- 2005-today: Z-Corp Color 3D-Printer

- 2013-today: EOS Formiga 100 with PA12/PA2200 Performance for springs, flexible hinges, and all kind of robots

- 2013-2015: Ultimaker S2 with PLA orange

- 2013-today: Arburg Freeformer for Research

- 2015-today: Objet PRIME30 for Research

- 2016-today: Formlab FORM2+ with Clear V4 in 50µm resolution for the production of links and fits for precision-engineering mechanisms and motion machines with 2.5mm to 1mm axis diameter

- 2017-2019: Kumovis R1: PEEK 1.75, printing never became a stable process

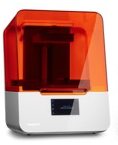

- 2020-today: Formlab FORM3B with Model V2 in 50µm resolution for the production of links and fits for precision-engineering mechanisms and motion machines 2.5mm to 1mm axis diameter

- 2020-today: Anycubic Predator: PLA 1.75mm, 100mm/s Speed, 0.3mm resolution for the production of the arm segments up to 380 mm of the LCLYK1 robot (no fittings/geometry adjustment)

- 2022-today: Intamsys FUNMAT HT: PEEK 1.75mm, 100mm/s Speed, 0.1mm resolution for the production of the medical instrument

The professional design of mechanisms and robots, which are 3D printed and are to be used in daily use with humans (humans can generate on average about 100W of work power), should be made taking into account the design rules for plastic components. A very good manual is available from AlliedSignal Plastics using the registered Trademark Modulus